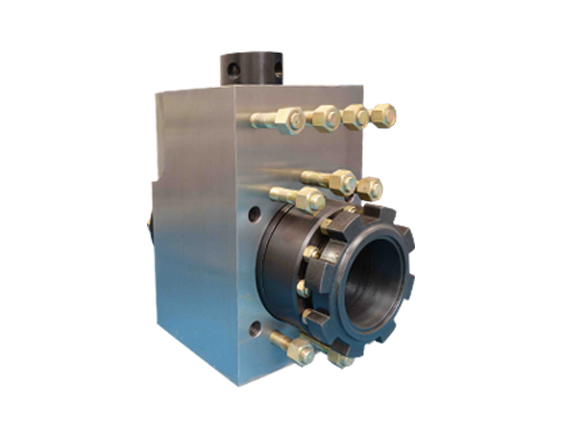

Mud Pump Module

Mud Pump Module

Mud Pump Liner

Mud Pump Liner

Pressure Gauge

Pressure Gauge

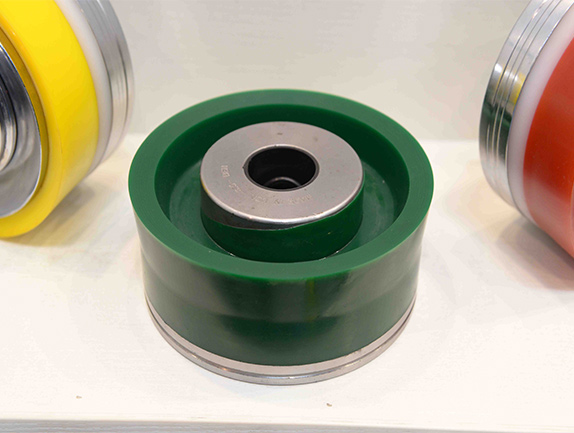

Mud Pump Piston

Mud Pump Piston

Mud Pump Valve

Mud Pump Valve

Rubber Seals

Rubber Seals

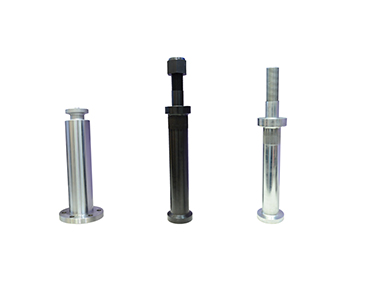

Mud Pump Piston Rod

Mud Pump Piston Rod

Mud Pump Pony Rod

Mud Pump Pony Rod

Mud Pump Wear Plate

Mud Pump Wear Plate

Pulsation Dampener

Pulsation Dampener

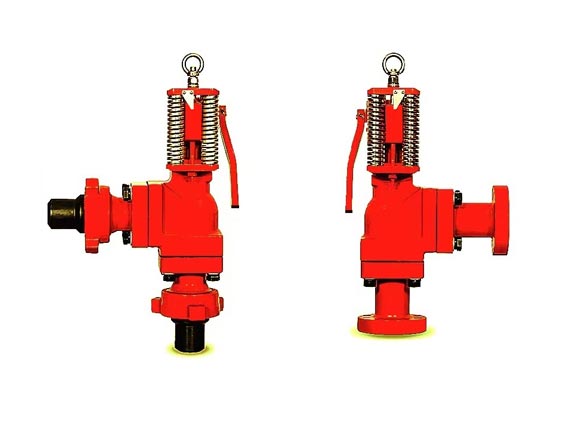

Pressure Relief Valve

Pressure Relief Valve

Centrifugal Pump

Centrifugal Pump

Valve Seat Puller

Valve Seat Puller

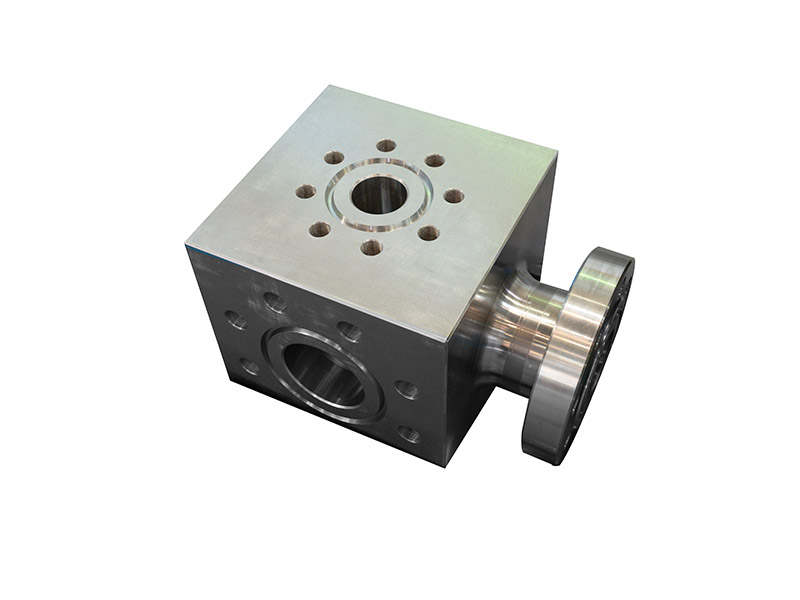

Manifold

Manifold

Crosshead

Crosshead

Crankshaft Assy

Crankshaft Assy

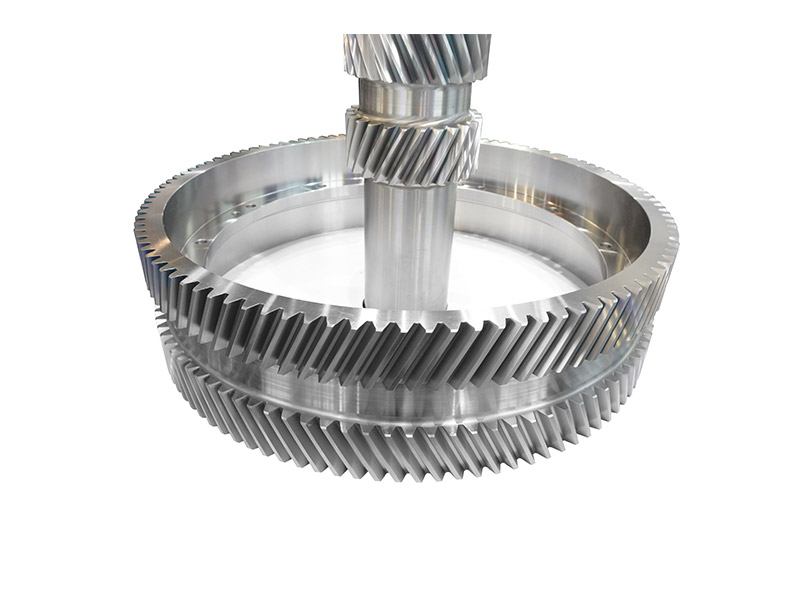

Pinion Shaft Assy

Pinion Shaft Assy

Four- way connection, Five- way connection

Four- way connection, Five- way connection

Mud Pump Big Gear Ring

Mud Pump Big Gear Ring

Spring Reset Safety Valve

Spring Reset Safety Valve

Shandong Rundong Petroleum Machinery Co., Ltd is major in manufacturing oil drilling mud pump spare parts and drilling tools, in which liners, pistons and valves that developed new have got national patent certificate. Mud pump parts we manufactured can be totally exchangeable with spare parts from original manufacturer, and have excellent performance especially in drilling conditions of high temperature, high pressure, oil base mud, acid base mud and high sand content mud etc.

Our company is nominated supplier of CNOOC, CNPC, SINOPEC, and enjoy good reputations. We have regular transactions with Customers of America, Germany, Canada, Russia, Belarus, Poland, Kazakhstan, Abu Dhabi, Iran, Vietnam, Pakistan.

We have been committed to continuous optimization and upgrading of drilling mud pump products.We accumulate rich first-hand technical information through our service to drilling projects, for example different material products’ performance under different drilling conditions. Our aim is to make products manufactured can be more suitable for oilfield drilling needs, and our goal is where there is oil, there is Deshi Brand products.

Products are produced according to ISO9001 quality system,APISpec7K standard, and each process can be tracked, recorded and traceable

Years of production experience accumulation and continuous innovation, make parts manufacturing process more sophisticated, products service time more longer, cost performance more higher. Drilling cost can be effectively reduced by taking these products.

Import spare parts such as valve module, crankshaft, pinion shaft’s material are high quality alloy steel,The power end herringbone gear adopts the grinding process, the gear precision is high, the processing precision of the matching components is much more higher, which can make the whole mud pump can run more smoothly.

High exchangeable content, most of International brand and Chinese brand mud pump parts can be provided, and rich inventory.

Production and quality inspection are separated, different process have different people to responsible, inspection methods are advanced, and have high-end inspection laboratories and detectors.

The products have excellent low temperature resistance and can be used normally in low temperature drilling conditions, minimum temperature can be - 45 °C.

Excellent anti-corrosion performance, can adapt to high salinity coastal and marine environment.

We can customize the most practical accessories for customers, according to the actual drilling conditions.

Perfect after-sales service, quick service response,wide service network, and strong technical ability.

| Model of Pump | Products Range | Products Name |

| F500、F800 、F1000、F1300、 F1600、F-1600HL 、F-2200HL | Hydraulic end products and power end products | Module, Liner, Piston, Valve body, valve seat, piston rod, pony rod, flanges, crosshead assy, air capsule, crankshaft, pinion shaft, connecting rod, manifold etc |

| HHF-1300、HHF-1600 、HH3NB-1600H、HH3NB-2200HL | Hydraulic end products and power end products | Module, Liner, Piston, Valve body, valve seat, piston rod, pony rod, flanges, crosshead assy, air capsule, crankshaft, pinion shaft, connecting rod, manifold etc |

| 7P-50、8P-80、9P-100、10P-130、12P-160、14P-220 | Hydraulic end products and power end products | Module, Liner, Piston, Valve body, valve seat, piston rod, pony rod, flanges, air capsule, manifold etc |

| PZ-7、 PZ-8、 PZ-9 、PZ-10、PZ-11 | Hydraulic end products | Module, Liner, Piston, Valve body, valve seat, piston rod, pony rod, flanges, air capsule, manifold etc |

| UNB600、UNBT950,、UNBT950L、 UNBT1180 | Hydraulic end products | Module, Liner, Piston, Valve body, valve seat, piston rod, pony rod etc |

Call us on:

Call us on:  Email Us:

Email Us:  No. 235, Weigao Garden, Torch High tech Industrial Development Zone, Weihai City, Shandong Province, China

No. 235, Weigao Garden, Torch High tech Industrial Development Zone, Weihai City, Shandong Province, China